Innovation with

integrity and ingenuity

- Site

- About us

- …

- Site

- About us

Innovation with

integrity and ingenuity

- Site

- About us

- …

- Site

- About us

At SDT, we build partnerships on quality, integrity, and innovation. Our aluminum die castings, value-added services, and dedicated team set the industry standard delivering consistent excellence in every component we produce.

Our Commitment to You

We don't just meet expectations; we redefine them.

✅ Unmatched Quality

• Every part undergoes rigorous Computer-Generated PPAP (Production Part Approval Process).

• Continuous improvement initiatives to ensure zero defects.

✅ Competitive Value

• Lean operations minimize overhead, passing savings to you.

• Transparent pricing with no hidden costs.

✅ Reliable Delivery

• On-time production, every time.

• Committed to supporting global manufacturing excellence.

Comprehensive Capabilities

End-to-End Solutions for Your Needs:

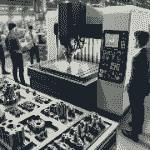

1. High-Pressure Die Casting

• Precision aluminum castings for automotive, aerospace, and industrial applications.

• Complex geometries with tight tolerances (±0.002").

2. Secondary Machining

Partnered with top-tier machine shops for milling, drilling, and threading.

3. Finishing Services

• Anodizing: This electrochemical process enhances the natural oxide layer on aluminum and other non-ferrous metals. Anodizing increases corrosion resistance, improves surface hardness, and allows for a variety of color finishes. It is ideal for applications requiring durability and aesthetic appeal.

• Powder Coating: A dry finishing process that applies a fine powder to metal surfaces, which is then cured under heat to form a tough, protective layer. Powder coating provides a uniform finish that is resistant to chipping, scratching, fading, and wearing. It is suitable for both indoor and outdoor applications and offers a wide range of colors and textures.

• Liquid Paint: This traditional finishing method involves applying liquid paint to surfaces using various techniques such as spraying, brushing, or dipping. Liquid paint provides excellent coverage and can be formulated for specific properties, including UV resistance, gloss levels, and color matching. It is versatile and can be used on a variety of materials.

• Plating: A process that involves depositing a layer of metal onto a surface to enhance its properties. Common types of plating include electroplating, which uses electrical current to bond the metal, and electroless plating, which relies on chemical reactions. Plating improves corrosion resistance, wear resistance, and can provide a decorative finish.

• Surface Treatments: This encompasses a variety of processes designed to modify the surface characteristics of materials. Treatments may include passivation to enhance corrosion resistance, chemical etching for improved adhesion, and shot blasting for surface preparation. These treatments can improve the performance and longevity of the finished product.

• Quality assured through 100% inspection (CMM/X-ray).

Why Choose SDT?

• Trusted Partnerships: Collaborations with nationally recognized tooling and finishing experts.

• Proven Process: From design to delivery, we're with you at every step.

• Your Success, Our Mission: We measure our success by yours.

OEM

Original Equipment Manufacturing

At SDT, we are able to take your product from an idea, work with you to develop the design, and use our in-house equipment to bring a tangible product to the market.

Engineering

We enjoy challenges.

Specialists in manufacturing high complexity castings adhering to the tightest dimensional tolerances, leakage requirements, and geometrical complexity.

High Quality Surface finishing

Advanced Manufacturing Processes

CNC Machining, Surface Coating, and protection. Our engineers work to achieve the desired finish specified for each component in production.

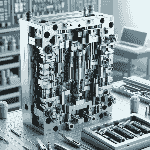

Tooling Design

We enjoy challenges.

We can assist in designing and manufacturing the perfect mould/die/tooling for your product by providing creative solutions to tooling design, ensuring the product remains true to specification.

© 2009-2025 by SDT

Smart Diecasting Technology (Suzhou) co,. Ltd

苏州圣美特压铸科技有限公司